In today’s dynamic business environment, companies constantly seek ways to optimize operations and reduce costs. One area gaining relevance is reverse logistics, which involves managing the return of products from consumers to manufacturers for reuse, recycling, or disposal. To efficiently handle this task, many companies are turning to outsourcing. In this article, we explore key outsourcing techniques in reverse logistics and how they contribute to cost reduction.

What is Outsourcing in Reverse Logistics?

Outsourcing in reverse logistics involves delegating processes related to product returns and management to specialized third-party companies. By outsourcing these tasks, businesses can focus on their core competencies. This strategy not only improves operational efficiency but also offers several economic benefits.

Key Outsourcing Techniques in Reverse Logistics

Subcontracting Return Processes:

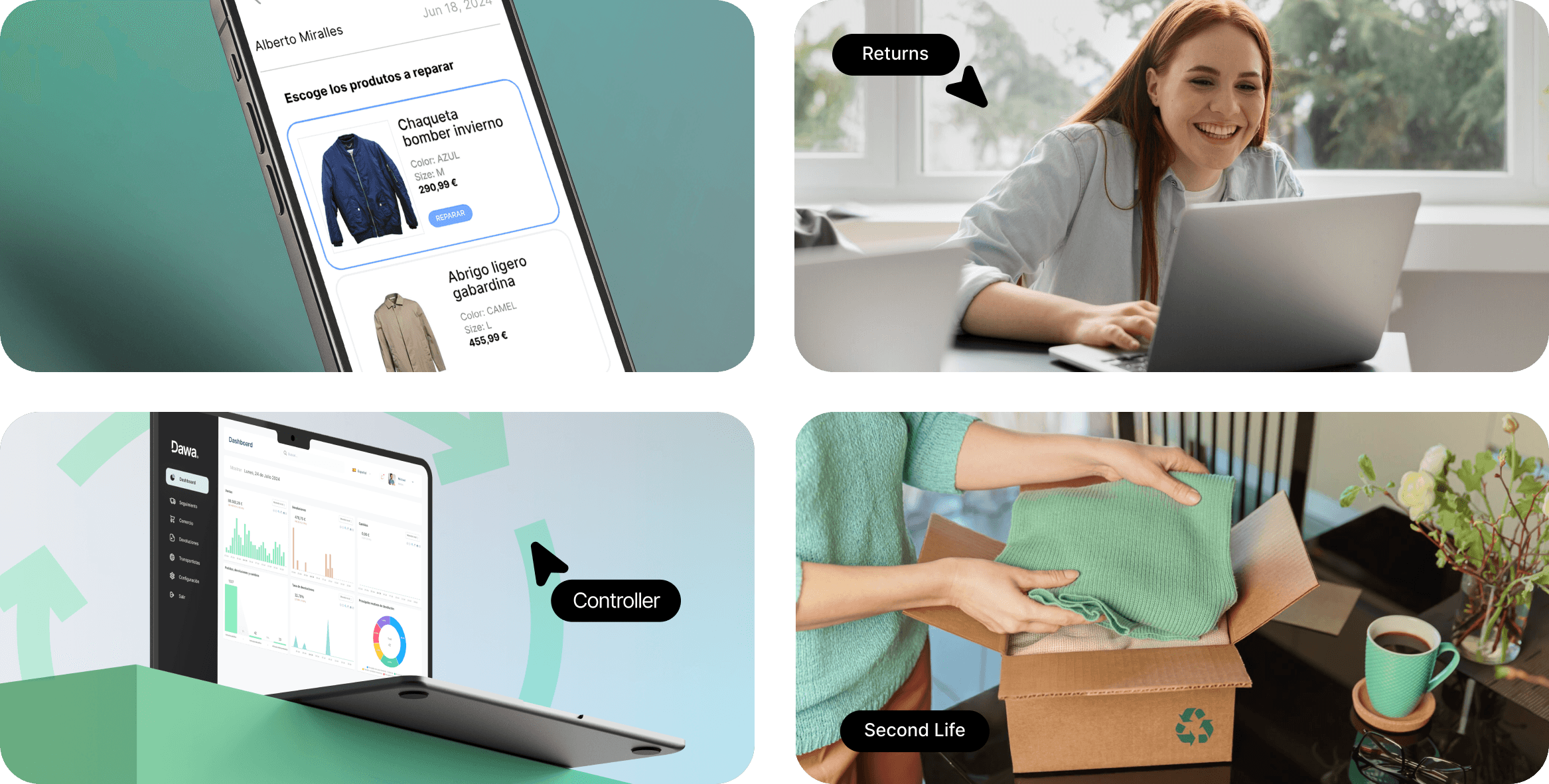

A common technique is subcontracting return processes. Companies partner with logistics providers specializing in return management, handling product receipt, sorting, and processing. This reduces operational costs and optimizes the resale of recovered products.

Waste Management and Recycling:

Outsourcing waste management and recycling is another crucial technique. Companies can hire recycling specialists to handle non-reusable product disposal and recover valuable materials, meeting environmental regulations and reducing waste disposal costs.

Repair and Refurbishment Services:

Repair and refurbishment services can also be outsourced. Specialized companies repair defective products or refurbish items for resale. This extends product lifecycles, minimizes the need for new product manufacturing, and enhances customer satisfaction by offering repair and refurbishment options.

Technology and Data Management:

Advanced technology and data management are essential for efficient reverse logistics. Companies can contract technology providers offering software solutions for tracking and analyzing returns. This improves product flow visibility, optimizes return routes and times, and enables long-term cost-saving data analysis.

Economic Benefits of Outsourcing in Reverse Logistics

Outsourcing in reverse logistics significantly contributes to cost reduction in several ways:

Economies of Scale: Specialized providers offer services at lower costs due to their large-scale operations.

Reduced Infrastructure Investments: Companies don’t need to invest in facilities and equipment to manage returns.

Improved Operational Efficiency: Logistics providers’ expertise and specialization optimize processes, reducing time and costs.

Flexibility and Scalability: Businesses can easily adjust contracted services based on their needs without incurring significant additional costs.

Conclusion

Outsourcing in reverse logistics is an effective strategy for companies looking to reduce costs and improve operational efficiency. By subcontracting key processes like return management, recycling, repair, and technology implementation, companies can focus on their core strengths while optimizing the handling of returned products. This synergy not only reduces costs but also contributes to more sustainable and customer-oriented operations.